Applications

Macoho's Wet Blast technology is now widely expanded to precision components such as materials for electronic components, printed circuit boards, printed wire boards, integrated circuits, and semiconductors. Many of these uses include deburring, deflashing, and improving adhesion (prevention of peeling). These are areas where dry blasting cannot be used.

Key Applications

Electronic Parts

This is an example of the introduction of our Wet Blasting equipment for electronic components such as PCB and semiconductors, as well as pretreatment of adhesive-resistant plastics (PI, LCP, PET, etc.).

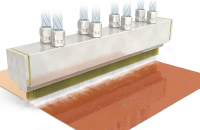

Black scale removal and part lubrication for cold forging

WLS (wet blasting + water-based lubricant application) is suitable for the lubrication process of cold forging lines.

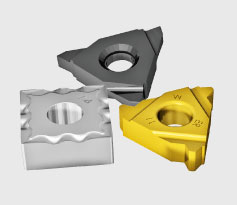

Coating pretreatment of cutting tools

Bonding pretreatment by wet blasting that completely removes impurities such as grinding sludge and releasing agents that adhere to the surface of carbide tools.

Application examples by industry

Automobile

Cleaning and pre-adhesion processing of anti-vibration parts

- Washing

- Roughening

Wet Blast Phosphating (WBP) is a surface treatment technique used for pretreatment for bonding of metal parts for anti-vibration rubber such as engine mounts, and brake parts.

Steel

Black scale removal and part lubrication for cold forging

- Removal

- Roughening

- Scraping

WLS (wet blasting + water-based lubricant application) is suitable for the lubrication process of cold forging lines.

Steel bar descaling

- Removal

- Scraping

This process scrapes off oxide scale (oxide film, black scale) from steel bars generated by heat treatment such as annealing. It is used as a pre-treatment for cold drawing and surface finishing.

Carbide Tools

Coating pretreatment of cutting tools

- Washing

Bonding pretreatment by wet blasting that completely removes impurities such as grinding sludge and releasing agents that adhere to the surface of carbide tools, thus enhancing the adhesion of coatings.

- Removal

An application of wet blasting, which removes the burrs off the carbide tools' cutting edges, thus extending their service life.

- Washing

- Removal

The application of wet blasting, which removes the droplets (granular protrusions) generated on the coating of tool surfaces without damaging the coating film.

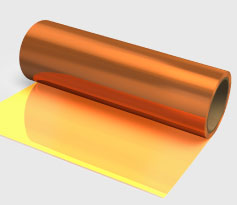

Electronic Parts

Improved adhesion for difficult-to-adhere resin materials

- Washing

- Roughening

Wet blasting pretreatment improves the plating adhesion strength of difficult-to-adhere resin materials (PI, LCP, PET, and others).

Improvement of underfill wettability

- Roughening

Fine surface roughening by wet blasting to enhance filling performance of the underfill (liquid curable resin for protecting the gold wires of IC chips).

- Removal

A surface treatment technique for pretreatment for plating, such as removal and cleaning of thin burrs (flash-burrs) generated on power semiconductor packages.

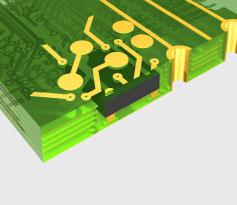

Scraping of the build-up substrate

- Scraping

Physical processing by wet blasting, which allows the filler-containing resin layer on the build-up substrate surface to be processed uniformly at high speed.

Substrate plating prewash

- Washing

- Roughening

This treatment is aimed at enhancing the adhesion of gold plating during the manufacture of printed wiring boards (PWB) and printed circuit boards (PCB), and reducing adhesion failure.

Removal of overmolding from embedded LED chips

- Scraping

This treatment scrapes the overmolding resin on the LED device that covers the chips as a result of manufacturing in order to expose the chips and electrodes.

Deburring of LED packages

- Washing

- Removal

- Scraping

This treatment washes out burrs and dirt on the LED package of the SMD chip (surface mount type) to prevent reflectivity loss on the reflector surface.

Plant Facilities/Maintenance

Maintenance of plant equipment

- Washing

This cleaning is a quick, easy, and physical way to remove oil, rust, and dirt from component parts that were removed from equipment or machines during regular maintenance.

Cleaning of critical parts for maintenance

- Washing

It is a safe and secure process done in a comfortable environment. It can help you maintain your equipment longer by making older, rusty and dirty parts as good as new.

Aircraft

Peening of airplane engine parts

- Peening

We have combined wet blasting technology with Macoho’s patented “wide gun” to come up with a new peening method called “wet peening”.

Other

Thin-film coating pretreatment

- Roughening

A strong coating film is formed on the surface by the anchor effect, which provides nano-level fine unevenness. There is no time dependence regardless of whether the material is organic or inorganic.

Beautification of exterior parts

- Peening

This is our unique, elaborate, new surface processing method, which is different from the conventional hairline finish, mirror finish, or satin finish.