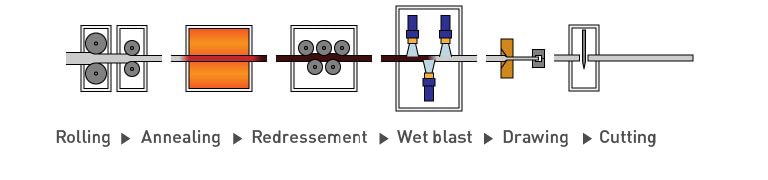

Steel bar descaling

What is the “removal of oxide scale from steel bars” by wet blasting?

This process scrapes off oxide scale (oxide film, black scale) from steel bars generated by heat treatment such as annealing. It is used as a pre-treatment for cold drawing and surface finishing.

Three features of wet blasting

- Processing done using small diameter SUS grit.

The water transport effect enables precise treatment using fine abrasives.

- Degreasing and descaling performed in one process.

No need for pre-degreasing because the abrasive removes the dirt while scraping the surface. Water also prevents re-attachment of the oil.

- Improved work environment

No dust is generated in the wet blasting process.

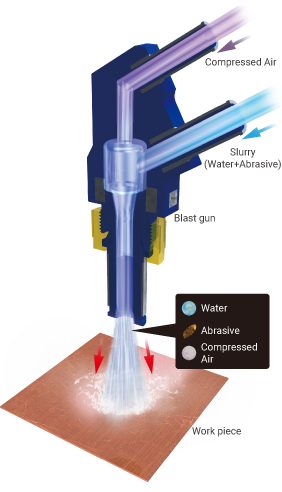

Wet Blasting Image

Wet blasting is a technique to project (spray) a mixture of abrasives and water at high speed with compressed air against a material to clean, process, and modify its surfaces. This technique allows fine abrasives to be used and is good at forming a fine uneven surface. The grinding of the workpiece surface is done while silmutaneously removing dirt and foreign matter.

Comparison with conventional methods

Comparison with shot blasting

| |

Shot Blasting |

Wet Blasting |

| Projection method |

Projecting steel balls with a rotating impeller |

Projecting a mixture of small-diameter grit abrasive and water with compressed air |

| Quality |

Residue of abrasives and debris remain on the scale. |

No residue → Abrasives scrape off the oxide scale |

| Dents are large, requiring finishing. |

- Reduced surface roughness after drawing.

- Improved processability → Improved lubricant retention and reduced residual stress due to fine roughened surfaces.

|

| Cost |

Many consumables are used for projecting over a wide area. |

Limited consumables due to projection (spray) aimed at the workpieces → Maintenance costs reduced by 1/2. |

| Environment |

There are dust-related risks due (fire, poor working environment). |

No measures needed to deal with dust since it is not generated (wet method). |

Comparison with “pickling (chemical treatment)”

| |

Pickling (chemical treatment) |

Wet Blasting |

| Quality |

Contact areas between workpieces are not uniformly processed. |

- No uneven processing → Each workpiece is fed by roller to be processed individually.

- Inline processing up to drawing is possible.

|

| Costs |

It takes time to etch the alloy material in order to remove scale. |

Since abrasives scrape off the oxide scale, this processing can be done for any material. |

| Environment |

Generation of neutralized sludge. |

Sludge generated is 1/20 or less → No acid or alkali used. |

| It is difficult to install new equipment because a large and heavy chemical bath is required. |

It is easy to build new production lines → Space savings and no special modifications required. |

Problems with conventional scale removal processes

| Descaling of annealed materials and alloy steels is difficult |

| Mechanical descaling |

Pickling (chemical treatment) |

| Shot blasting |

Peening |

- Contact areas between workpieces are not uniformly processed.

- Energy costs are huge.

- A large amount of inventory is necessary due to the huge amount of time required for processing.

|

- Cannot be used before finishing because of remaining scale.

- Embeds scale into the bar surface.

|

- Uniform processing is not possible due to misalignment.

- Machining allowance is large.

|

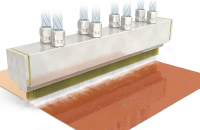

Wet Blasting Application Example

Three Points

- Focused spraying (projection) with compact guns ensures descaling.

- Reduced maintenance costs due to the use of the round nozzles resulting in limited wear and tear.

- This descaling method does not use acid or alkali, thus resulting in a reduction of sludge generated.