Cleaning of critical parts for maintenance

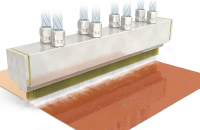

Processing Details

- Washing

Restoring/Overhauling/Cleaning of essential parts

Any item around us gets affected as time passes in terms of the materials as well as the performance. This is why maintenance is required to extend its lifetime or avoid troubles. Macoho's Wet Blast technology can make your maintenance time much shorter by effectively removing rust or thick contamination in the blink of an eye!

Features

1.

Speedy removal of thick contamination

The secret is tens of millions of particles shot at high-speed to a work piece. The blast removes contamination and water washes away the substance at the same time. There is no residue on the surface.

2.

Complete cleaning on rough surface like engine parts with the minimum damage of work pieces

Because of water that delivers fine abrasives several tens of μm in size, the slurry reaches into narrow spaces and gaps.

3.

Applicable to various materials

Steel, aluminum, stainless steel, resin etc. You can process many types of materials with our Wet Blasting equipment.

4.

We care about you! We care about our planet!

Because abrasives are mixed in water, there is no risk of dust fire nor any harmful dust caused that will get into your surroundings.

Our eqipment is also Eco-friendly with special circulation systems that reduces waste water.

Advantages and disadvantages of Wet Blast

| Techniques | Wet Blast | Chemical Process | Brushing | Sand Blast |

|---|---|---|---|---|

| Processing Time | ★★★ Quick |

★ The reaction needs time |

★ Requires lots of work and time |

★★★ Quick |

| Range of contamination types | ★★★ Effective for any types |

★★ Needs certain type of chemical depend on contamination |

★ Carbon and grease are likely to remain |

★★ No degreasing |

| Rough surface cleaning | ★★★ Separated abrasives reach into narrow spaces |

★★★ The liquid reaches into narrow spaces |

★ Until where a brush can physically reach |

★★★ Separated abrasives reach into narrow spaces |

| Damage on work pieces | ★★★ Hardly |

★★★ None |

★ Requires sensitive adjustment |

★ The power is too strong and causes rough surface |

| Material of work pieces | ★★★ Effective for any types |

★ Not available for materials that react with chemical |

★★★ Effective for any types |

★★★ Effective for any types |

| Dust | ★★★ No dust unless particles in water get completely dry |

★★★ None |

★ Yes |

★ Risk of fire. Needs dust collectors |

| Waste water/Waste | ★★ Crushed abrasives and grinding scraps |

★ Yes |

★★★ Yes but a little |

★★ Crushed abrasives and grinding scraps |

Examples

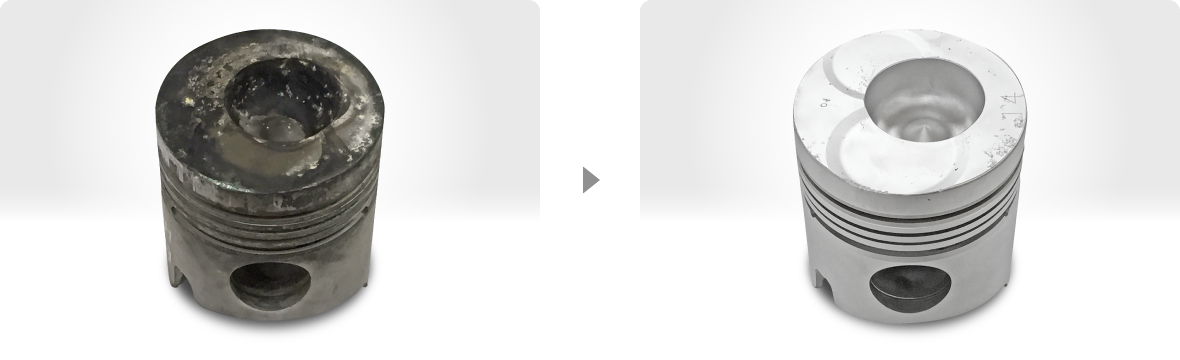

Cleaning - A heavy machinery piston

Cleaning - A heavy machinery pistonMaterial: Alminium

Abrasive: Glass beads

Processing time: 5 minutes

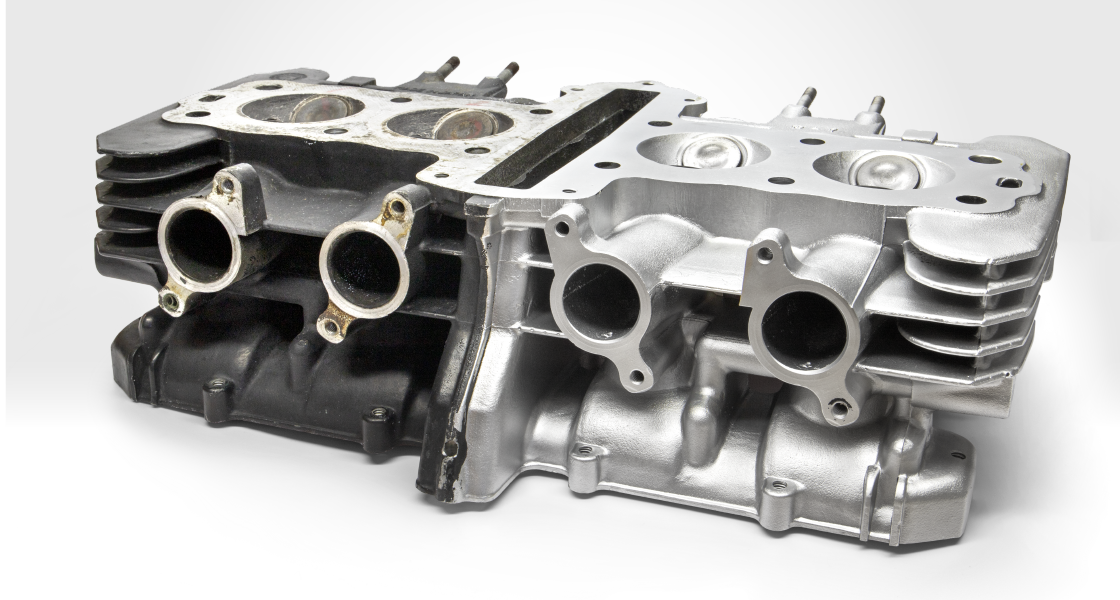

Cleaning - A cylinder block

Cleaning - A cylinder blockMaterial: Alminium

Abrasive: Glass beads

Processing time: 25 minutes

Cleaning - Shield plate from a spattering machine

Cleaning - Shield plate from a spattering machineMaterial: Stainless steel

Abrasive: Stainless cast steel

Processing time: 10 minutes

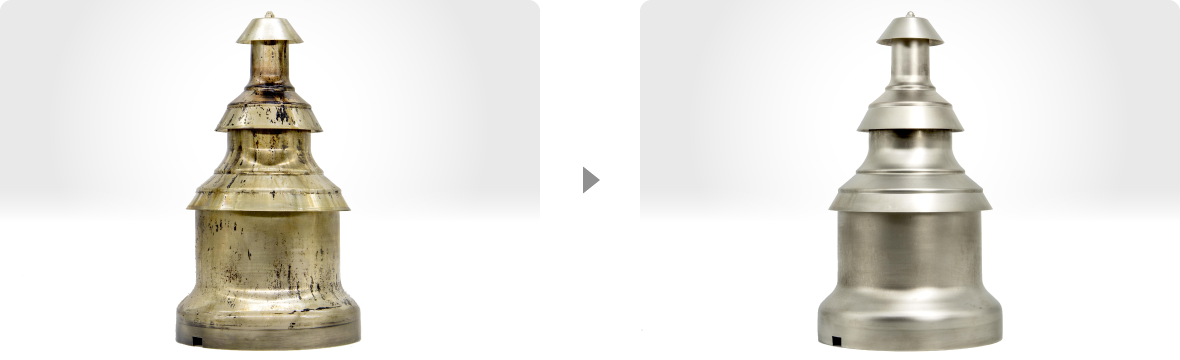

Degreasing - Vacuum pump

Degreasing - Vacuum pumpMaterial: Plated steel

Abrasive: Zirconia Beads

Processing time: 5 minutes

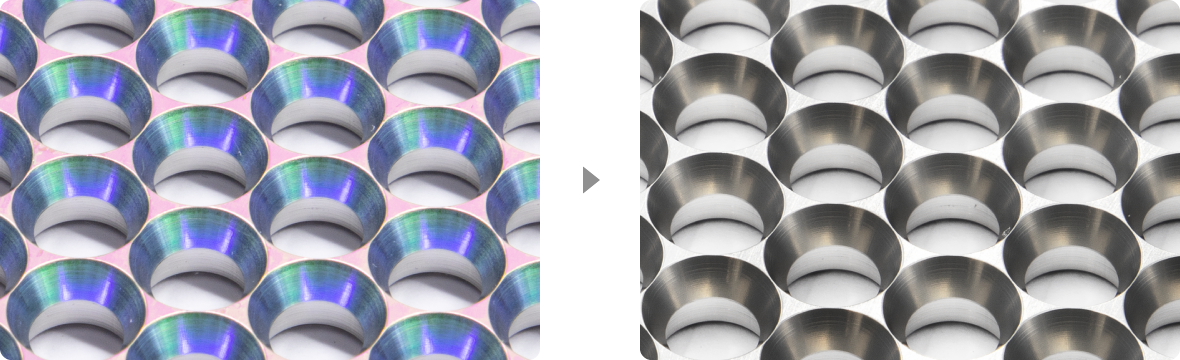

Film removal - Vapor deposition mask

Film removal - Vapor deposition maskMaterial: Stainless steel

Abrasive: Polygonal Aluminium

Processing time: 10 seconds