Droplet removal

Processing details

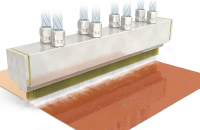

- Washing

- Removal

Wet Blast to remove drill droplets

Droplets (granular protrusions) generated on the coating applied to the tool surface are removed without damaging the coating film.

Problems with conventional processing

- Three-dimensional workpieces have some parts that are difficult to polish with a polish grinder or the like.

- The coating film is also scraped at the same time as droplets are removed.

- Difficult to automate polishing process.

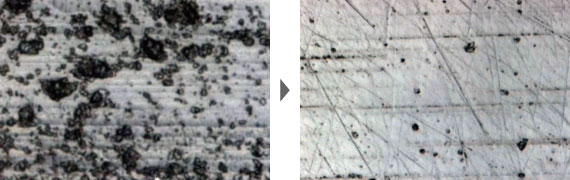

Comparison before and after processing

The treated surface becomes shiny without scratches. *Not visible to the naked eye.

Enlarged Surface Image

The black dots are the droplets.

* The black spots after processing are traces of threshing (dents from which droplets have been removed).

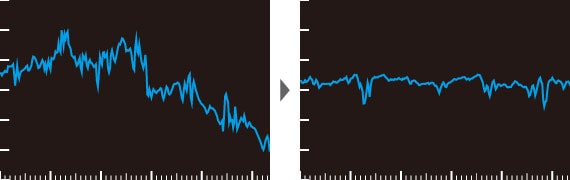

Surface Roughness