Coating pretreatment of cutting tools

Processing Details

- Washing

Coating pretreatment by wet blasting

Bonding pretreatment by wet blasting that completely removes impurities such as grinding sludge and releasing agents that adhere to the surface of carbide tools used for NC lathe machining, thus enhancing the adhesion of coatings.

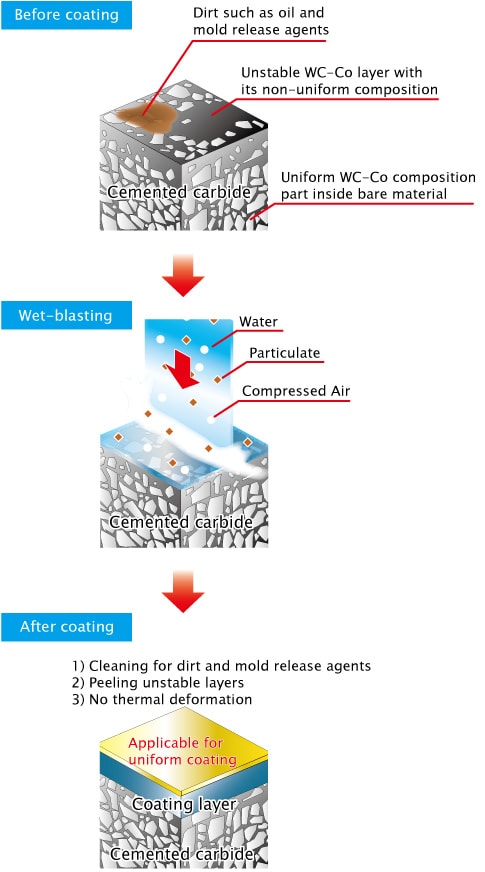

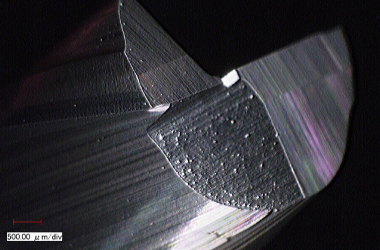

Characteristics of processing before coating (Ultra-cleansing power)

- With wet blasting it is possible to remove all kinds of dirt, such as die release materials, oil, and oxidized matter which have adhered to the surface of the machinery tools and dies.

- By grinding the surface layer, the bare base material is exposed uniformly.

Problems with conventional processing methods

| Cleaning Process | Process flow of roughening and grinding | |

|---|---|---|

| [Chemical] | [Physical polishing] | [Dry Blasting] |

|

|

|

Solutions (Features of wet-blasting technology are…)

- Perfect cleaning can be made as it removes every single dirt made of various materials. Surface grinding is done at the sub-micron level.

- It is environmentally friendly due to non-use of chemicals and a physical cleaning method being applied.

- Uniform cleaning can be made as micro-particles are processed along with surface topography.

- Loose abrasive processing makes no scratches on the parts.

- No thermal deformation occurs on the parts since their surface is processed along with water cooling.

- There is no residue nor any dirt remaining since the water washes them off while cleaning.

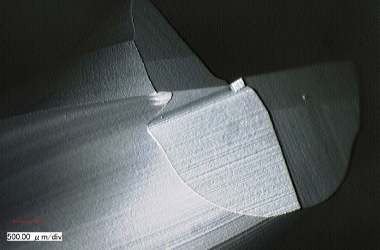

Before Coating

After Wet Blasting

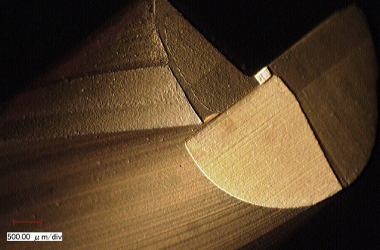

After Coating

Examples of applications and products

| [Application Examples] | Examples of Applicable Products |

|---|---|

|

|