Semiconductor resin deburring

Processing Details

- Removal

Process Objective

As a pre-treatment for the plating process, the burrs caused at the resin molding of the semiconductor packaging are removed.

Types of burrs

Dam-burrs

Burrs that fill out between the leads.

It is possible to remove burrs by conventional burr removal method.

Side-burrs

Thick burrs on the side of the leads.

It is possible to remove burrs by conventional burr removal method.

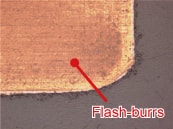

Flash-burrs

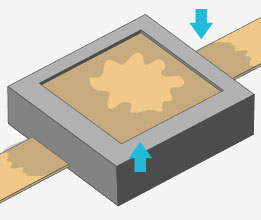

Thinner burrs on leads and heat sink.

Demand for flash-burr removal is increasing due to the technical trends of smaller packaging and thinner products. Therefore a burr removal method with a reasonable price and stable quality is needed.

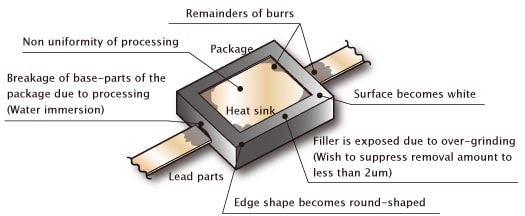

Problems related to flash-burr removal

Benefits of flash-burr removal by wet blasting

- Burrs can be perfectly removed by uniform processing.

- Package does not become white.

- Processing power can be controlled at the sub-micron level.

Wet Blasting Characteristics

1)By precision physical cleaning, flash-burrs on the electrode plane can be completely removed.

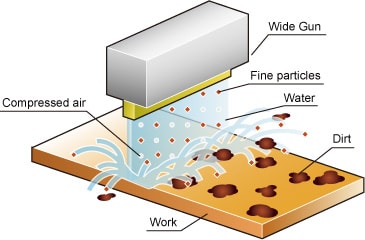

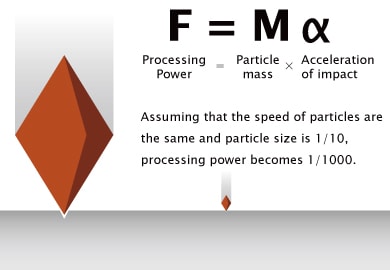

Principles of Cleaning

Using the energy of the water and abrasives colliding with the surface, dirt and foreign matter are removed while simultaneously scraping off the surface of the part.

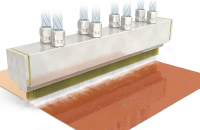

2)Reduction of non-uniform processing by using Macoho's original and patented wide gun.

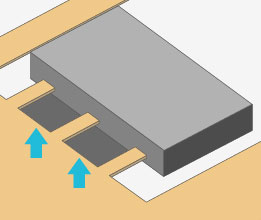

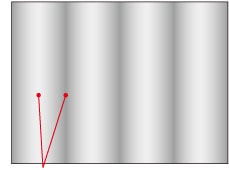

Conventional Guns (nozzles)

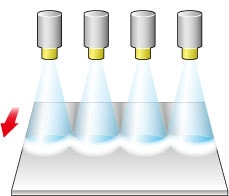

Simultaneous spraying by multiple guns.

Non-uniform processing occurs.

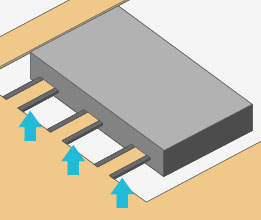

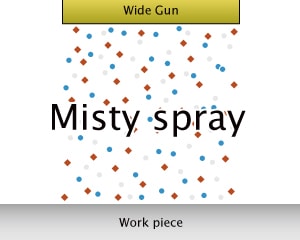

Wide Gun

Projection by one gun in accordance with the processing width.

It is possible to uniformly process the whole surface.

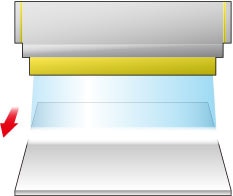

3) Soft processing using isolated abrasives makes it possible to reduce or even eliminate damage to the package.

Less pressure onto the work piece is applied by continuous pulse processing to its surface.

4)It is possible to reduce or even eliminate damage to the package’s surface by using low-pressure super-fine abrasive processing.

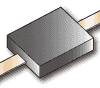

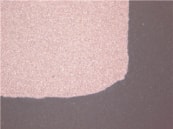

Examples of flash-burrs

| Untreated | After Wet Blasting | |

|---|---|---|

Package Surface |

|

|

Package Surface |

|

|

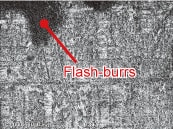

| Heat sink surface - Electron microscope (SEM) |

|

|

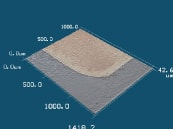

| Heat sink surface - Laser microscope |

|

|