Improvement of underfill wettability

Processing Details

- Roughening

High density and performance supported by the surface quality improvement technology

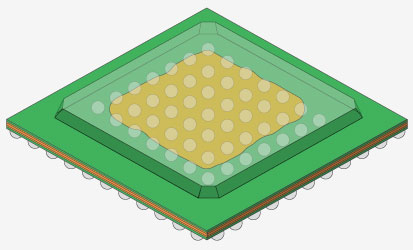

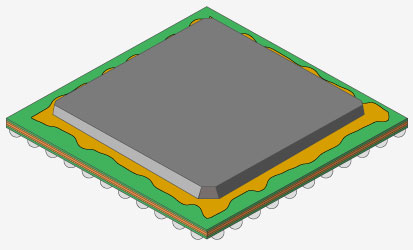

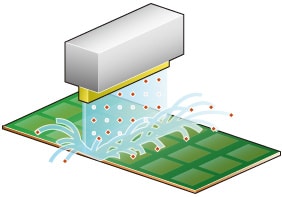

Wet blasting is used to finely roughen the surface of a flip-chip package substrate, which can reduce the size of the IC package compared to wire bonding. This enhances the filling performance of the underfill (liquid curable resin for protecting the gold wires of IC chips).

Issues

- The surface modification effect is time dependent.

= Difficult to control wettability - The underfill has poor fillability and fluidity, so the liquid does not spread out well. Or bleeding out occurs.

Liquid does not spread.

It bleeds out.

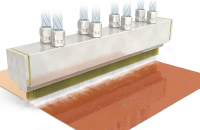

Processing Image

- Cleaning and removal of foreign matter from the SR surface.

- Improve wettability by expanding the surface area.

- Pinning prevents bleeding from occurring.